Sir Isaac Pitman and Sons Ltd Year Published. Therefore a suit able jig-fixture assembly is designed to carry out the machining process.

Jig Or Fixture Design Problems And Solutions

Due to design constraints it is subjected for an after-machining process ie.

. The current mechanism of jig and fixture design in the machine failed to perform successfully to the desired force that produced by the hydraulic cylinder 16286lbs. Component- Design to be studied carefully Ensure work is performed in a proper sequence Maximum operations should be performed on a machine in single setting 2. The maximum holding force was the importance parameter to determine whether the new jig and fixture configuration was able to locate correctly and provide.

Verify the dimensional accuracy of the jigs and fixture. Whereas a jig holds locates and as well as guides the tool. Based on the overall factors the design of tool bodies of jigs and fixtures can be segregated into three main categories.

If the blank size is too large it will result in interference. Design a box jig for a pipe elbow having flanges at the two ends which are orthogonal. The fixtures are heavier in construction and are bolted rigidly on the machine table.

2 The chip evacuation of the fixture is smooth. Services such as design assistance andhelp resolve design problems is the group of skilled problem solving where their product is involved arepeople in the toolroom. For example which are the problems in the design for the clamping of parts or what process must be done with.

Graded problems analysed and explained for production engineering students and draughtsmen. Download JIG AND FIXTURE DESIGN PDF for free. Another one is the high initial set up costs and time.

In addition to developing designs for effi- Preformed materials can greatly reduce tooling costscient and accurate jigs and fixtures the tool designer by eliminating many machining operations. The design consideration of jigs and fixtures 1 The blank allowance of the machined part. Use ribs and fillets to increase rigidity.

Below are the steps to take to make a jig and fixture using 3D printing. Part of MIL-STD-810G above shows how critical is a Jig or Vibration Test Fixture. Capacity of the machine-Careful consideration to be performed on type and capacity of machine.

Greeting to the all of the experts in the university im studing about the automotive a ssembly industry and i want to deepen into the area of jigs and fixturess desing. The jig is intended for drilling holes at the two faces of the flanges four in one side and two in the other. Final assembly including tail wing 11 22 Problem Statement.

It is Components of machine-tool installations specially designed in each case to position the work piece hold it firmly in place and guide the motion of the power tool eg a punch press. Disadvantages of Jigs and Fixtures. Definition of jig and fixture i Jigs and fixtures.

Face milling for chipping off the extra material from the final tail wing. I would like to know which are the common issues at the moment to joins the car parts. When jig fixtures are used in machining it is necessary to clarify the basic positioning problems and to deal with the positioning problems in place then the accuracy of machining will be more accurate and the quality of machining will also be improved invisibly.

The drilling jig designed has the following salient features. A fixture holds and positions the work but does not guide the tool. Applications of Jigs and Fixtures.

They have their own weaknesses and strengths and they are a better fit for some particular work situations. Product which is over tested will be less cost effective. Specific subjects include methods of gaging work pieces ease and simplicity of operation assembly methods capital evaluation and techniques for locating and holding work pieces time studies tool steels bending allowances and reverse engineering techniques.

Good - 1st Edition - Good - VINTAGESTAN BOOKS Title. Find more similar flip PDFs like JIG AND FIXTURE DESIGN. Whereas the jigs are made lighter for quicker handling and clamping with the table is often unnecessary.

Increase the jig and fixture durability by using metal threaded inserts. Available now at AbeBookscouk - Hardcover - Sir Isaac Pitman and Sons Ltd - 1950 - Book Condition. Ii Definition of jig Jig can be defined as follows a A fixture with an additional feature of.

Can wear away over time. Due to the limited processing space of the machine tool jigs and. Although there are so many advantages by using Jigs and Fixtures but also there are some disadvantages too.

Jig and Fixture Design. Jigs and fixtures for production machining processes are covered. Cast Welded Built-Up Each of these types of tool bodies has its own functionality.

JIG AND FIXTURE DESIGN was published by sureshkumars on 2017-07-31. Jig fixture positioning problem. Factors to be considered for design of Jigs and Fixtures 1.

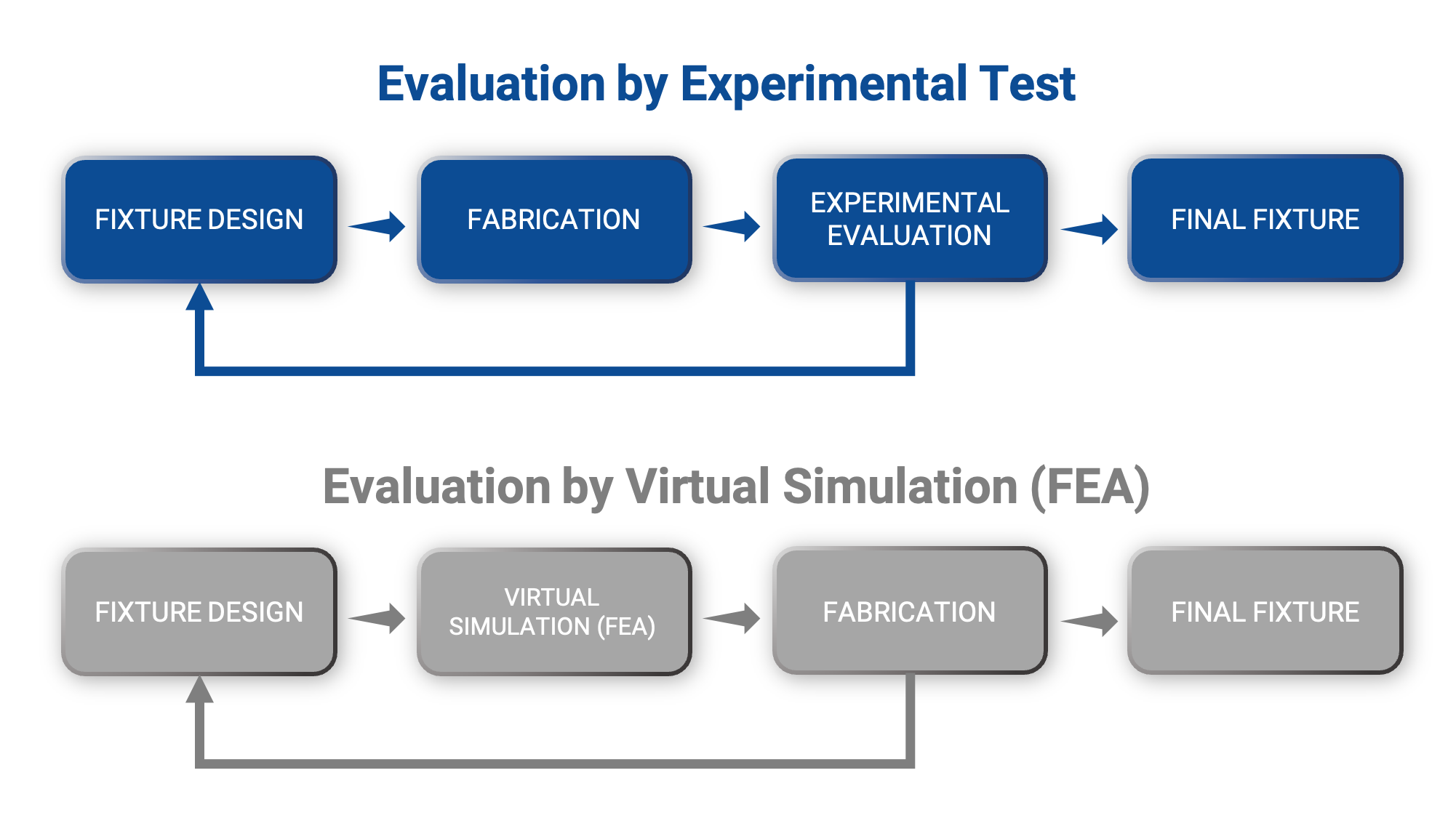

Common problems in Jig or Vibration Test Fixture Test fixture which is not properly designed will over tested or under tested product. Unit 1 deals with objectives of tool design functions types elements and advantages of jigs and fixtures principles of location and clamping locating methods and devices drill bushes and jig. When-is responsible for finding ways to keep the cost of spe- ever practical preformed materials such as drill rodscial tools as low as possible.

And can use a lot of material and be bulky. Design of a channel jig. You can do this using metrology tools.

Clamping Squares 3 Clamping Squares Set Of 4

Design Of A Milling Fixture Problem 1 Youtube

Jig Or Fixture Design Problems And Solutions

Taunton S Complete Illustrated Guide To Jigs Fixtures Complete Illustrated Guides Taunton By Sandor Nagyszalanczy Paperback In 2022 Jigs Book Organization Problem Solving Skills

Adjustable Replacement Tool Rest Sharpening Jig For 6 Inch Or 8 Inch Bench Grinders Best Backyardequip Com Wood Turning Chisels Wood Turning Bench Grinder

0 comments

Post a Comment